Many customers are interested in the working principle of rotary joints. Different specifications and models of rotary joints also have different working principles. Next, we will explain the working principle of rotary joints in the form of pictures and texts.

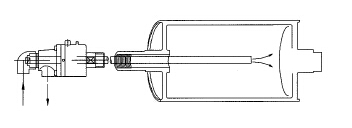

Daul Flow ( inner tube rotation) the working principle of rotary joints

The inner tube is tightly connected with the roller to prevent the fluid backflow and affect the heating efficiency of the roller.

Rotary joint working diagram:

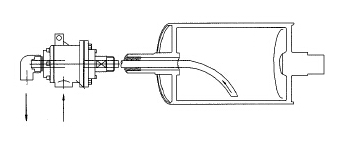

Daul Flow ( inner tube rotation) the working principle of rotary joints

The siphon is installed in the roller to remove condensed water. This type is mostly used for steam.

Working diagram:

Daul Flow ( inner tube rotation) the working principle of rotary joints

A rotary joint is installed at one end of the roller to allow fluid to enter and exit.

Working diagram:

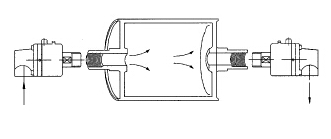

Single Flow the working principle of rotary joints

The rotary joint is a through-flow device at both ends of the drum. Fluid enters at one end and discharges at the other end. No inner tube is required.

Selection procedure of rotary joint

Firstly, the type of rotary joint is determined according to its structure:same side of the device,If the structure of the device determines that the input and output media are realized on the same side of the device, then the complex type rotary joint must be selected. If it on the both sides of the device, then a single-channel rotary joint must be selected.

If the equipment requires the transmission of multiple media or the medium output to multiple locations should be considered to choose a multi-channel type rotary joint.

Select the size of the rotary joint according to the medium flow.

According to the pressure of the medium and the speed of the equipment to choose the corresponding performance of the rotary joint.

If the user is not convenient to choose the type of rotary joint, the following parameters can be provided, our company is responsible for providing the selection for you.

①Structure and relevant dimensions of connection between equipment and rotary joint.

②The speed and direction of the rotary joint.

③ Media、Temperature and Pressure.

④Dimensions for connection of swivel joints and metal hoses.

Copyright © 2024 Siluzan All Rights Reserved.